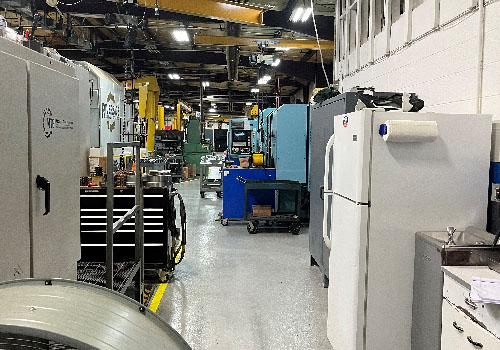

Our Hobbing Center consists of a full line of CNC hobbing equipment as well as manual machines. The Hobbing Center operates on two shifts, 18 hours per day.

Our CNC hobbing equipment consists of the following:

Our Bourn & Koch 400H's horizontal CNC gear hobbers allow us to cut up to 50 inches in length and approximately 12 inches in diameter. Our largest CNC Hobber, a Hurth Modul ZFWZ16, was added in December 2020. It has been fully refurbished with a full Fanuc 5 AXIS recontrol by Machine Tool Builders (MTS). It is a 5 Axis machine that can accommodate gearing as large as 63" diameter and up to 1.4 DP. It also has a 13.75" table bore diameter and a 51" cutting height from the table allowing this workhorse to cut shafting up to over 100" in length. MTB is well known in the gear industry for using older heavy duty platforms and turning them into new CNC gear cutting equipment. The Pfauter P900 can cut up to 35.4" diameter gears. This Hobber was a full FANUC 5 AXIS recontrol done by Machine Tool Builders (MTS). The Modul 800 CNC Hobber, is a full FANUC recontrol by MTB, and can cut up to 31.5 inches in diameter. All of our CNC hobbers have the ability to crown or taper cut as well. Our latest addition a Pfauter 630 CNC can cut up to 24" diameter gears and has been fully updated with a new NUM control that was recontrolled by Ron Peiffer of RPM Machine (Formerly co-owner of MTB)

The Hobbing Center also has a full list of manual gear hobbing equipment in its arsenal including a Phauter 1800, G&E 48HD and 1 Barber Colman. We also have a complement of a Red Ring shavers if you decide not to go with a ground gear.

Our Hobbing Center operates 18 hours a day, has 9 highly skilled machinists, and has a large supply of both metric and starndard hobs including a full complement of pre-grind depth hobs assuring we can get your project up and running quickly.